Our Products Have Gained Recognition From Customers And Are Being Continuously Exported To The Middle East And African Markets.

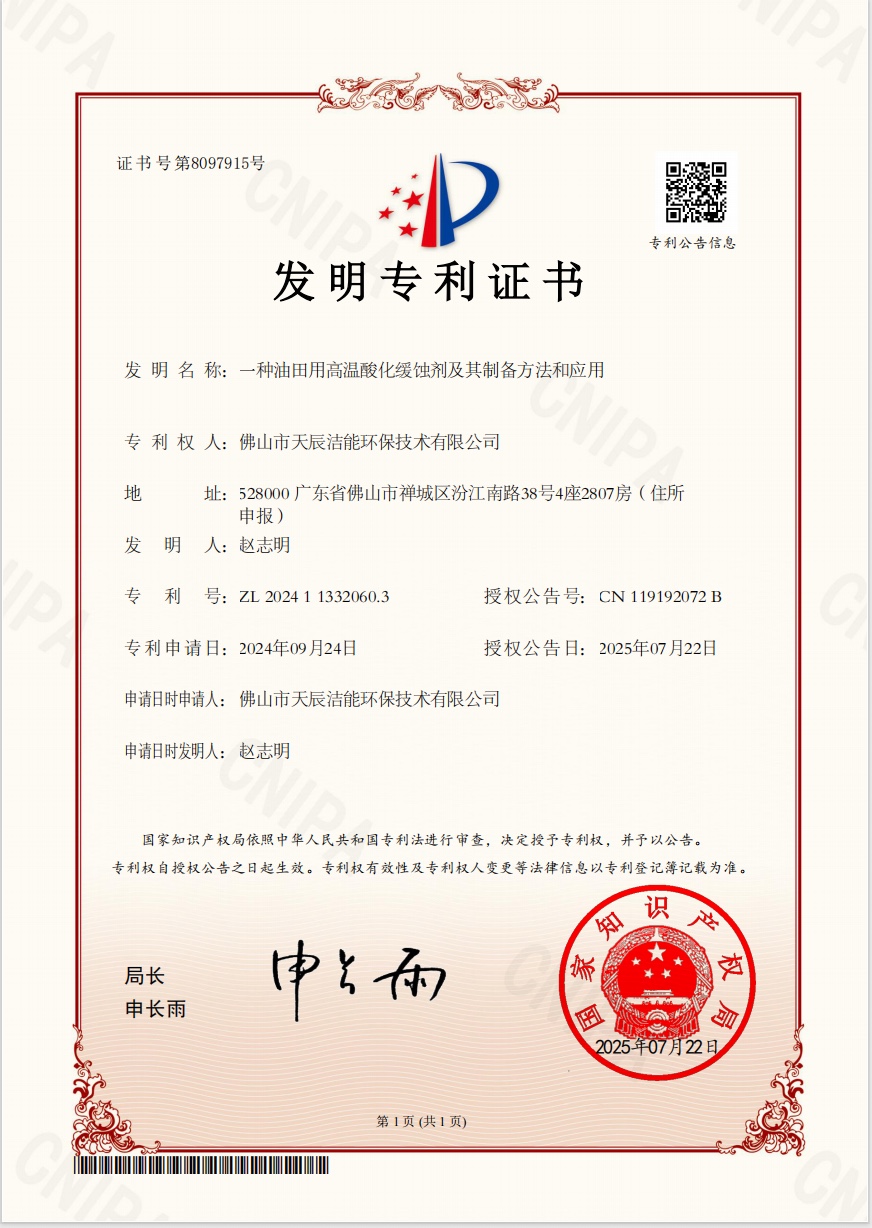

Our company has been granted another invention patent: High-Temperature Acidizing Corrosion Inhibitor for Oilfields, and Its Preparation Method and Application

At the start of the Chinese New Year, the company successfully fulfilled its commitment by delivering a fresh batch of orders to Middle Eastern customers. This timely action not only showcases the company's efficiency but also strengthens its business ties in the region.

We utilize the abundant salt lake resources in China, along with strategic technical collaboration of Chinese magnesium company which has advanced technology, to produce magnesium compound at high purity which fully meets the production standard of vanadium corrosion inhibitor

In some case, the gas turbine blade might have scale formation which is difficult to clean. The volume and quality of scale formation on gas turbine blade depends on many factors, such as the gas turbine load, burning temperature, the nebulization level of fuel oil, the quality of fuel oil, the cleaning method of turbine and so on. Under normal circumstances, vanadium corrosion inhibitor would react with metal compounds in fuel under high temperature, to form high-melting-point solid-state inorganic double salt. Most of the double salt will flow out with exhaust gas as solid ash, a small part would stick on blade surface and most of it can be washed off, but little residual could still remain especially on the root of stationary blade, which needs to be cleaned with machine during the outage maintenance. Here to provide the analysis of cause and advice of solution according to the fuel oil specification below as an example, any other on-site factors that could impact the blade scaling needs to be analyzed case by case.